Origin of the OLOID geometry

Cubes and inversion

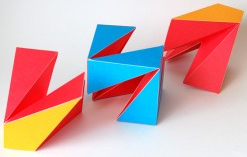

In 1929, the engineer and inventor Paul Schatz discovered a new geometric body and and a back then unknown type of movement: He divided a cube into 3 partial bodies in a certain way, examined the mobility of the middle partial body (blue-red in Fig. 1) and observed the shape of the movement. This is explained step by step below:

Divide a cube into 3 special partial bodies. The middle part (blue-red in Fig. 1) is the so-called “cube belt”, a 6-membered ring of uniform, pairwise mirror-symmetrical tetrahedrons.

The remaining 2 parts (orange-red in Fig. 1) are called “latch bodies” and are identical to each other.

All 3 parts have the same volume.

Take the cube belt, hold it so that you can invert it infinitely and discover the inversion movement.

- During a complete inversion of the cube belt, an oloid is drawn in space from each of the 4 cube diagonals an oloid is drawn in space. When doint this the length of the diagonals is always retained.

- By holding one of the 6 tetrahedra of the cube belt and observing the path of its opposite diagonal, the surface covered by it is an oloid.

- An oloid can also be described as an envelope shape of two congruent circles perpendicular to each other, where the circumference of one circle passes through the center of the other circle (see Fig. 2)

Mathematical facts

The surface area of a sphere with radius r and the surface area of an oloid with the same radius r (three times in the oloid, see Fig. 3) are identical: A = 4πr2

The volume of a sphere is V = (4/3) πr3 . Mathematically speaking, this results in the highest possible ratio of surface area to volume: A/V = 3/r.

The volume of an oloid cannot be calculated exactly, but can be approximated with V = 3.0524*r3.

This results in an approximation for the ratio A/V = 4/3 π/r

- On a slightly inclined plane, an oloid starts to roll very quickly. This can be explained by the fact that the surface of the oloid is in contact with the ground on a straight line, which means that the oloid only requires a very small amount of energy to be set in motion. This already low energy is even lower for a ball, for example, which is in contact with the surface at only one point. The very low static friction is an indicator of energy-efficient movement. With its single surface and two arc-shaped edges, the oloid is one of the few geometric bodies that touch the surface with its entire surface when rolling.

https://www.youtube.com/watch?v=GM3_JuFgJ2E - Another example is the sphericon, which also only has a continuous surface. In contrast to the oloid, the sphericon appears compressed, as the radius does not occur 3x in the body and the body can be described by two double cones rotated by 90° against each other. The surface area of a sphericon is calculated as A = 2*√2*πr 2 and the volume as V = 2/3*πr3. This results in a ratio of A/V= 3*√2/r that is √2 greater than that of the sphere.

- This means that the sphere has the best surface-to-volume ratio and the oloid has a slightly better ratio than the Sphericon.

- However, all 3 bodies have in common that the center of gravity corresponds to the center of the body.

Movement

In physics, translation and rotation are the two standard recognized forms of motion. The course of movement of the cube belt described in the previous section follows a three-dimensional '8' lying in space and thus opens up a third form of movement that is new in physics: INVERSION.

In order to cause an oloid to approximate its own rolling motion at a fixed location by means of a motor, the oloid must accordingly be mounted with two forks perpendicular to each other (at the height of the two centers of the circle in the oloid frame) on two shafts rotating in opposite directions to each other.

The use of an oval gear mechanism in the gearbox makes it possible to convert the rotation of the motor into a simultaneously different, mirror-symmetrical rotation of the two shafts. Further details on the mechanical drive can be found on the Internet: https://www.youtube.com/watch?v=r-lNe9AUwOg and https://www.youtube.com/watch?v=ssFZRQuJXJk

Rolling behavior of the oloid compared to different bodies

A sphere, an oloid, a cube and a cylinder are compared with each other in terms of volume, surface area and rolling surface. The radius and edge length are defined, and in the case of the cylinder, the height is defined accordingly. The sphericon is not shown, as it has already been shown in section 3 that the sphericon is located between the sphere and the oloid. The radius of the sphere, the cylinder and the oloid are randomly set to 2 without specifying the units. The edge length (cylinder height) is set to 4, so that the projection surfaces of the oloid, cube and cylinder are the same size.

The rolling behavior is analyzed for one full revolution, where the cylinder is rolled along its circumference. See top row in Fig. 5. It is a little problematic to compare the one-dimensional rolling of the sphere against the other rolling patterns, which are two-dimensional. Nevertheless, the comparison coefficient shows the optimum ratio of surface area to unrolled surface area of the oloid.

The following table summarizes the volume, the surface area and the rolling surface as well as their coefficients (surface area/rolled surface area). All parameters in SI units.

| Parameters | Sphere | OLOID | Cube | Cylinder |

|---|---|---|---|---|

| Radius r [m] | 2,00 | 2,00 | 2,00 | |

| Edge length a [m] | 4,00 | |||

| Height h [m] | 4,00 | |||

| Volume [m³] | 33,51 | 24,40 | 64,00 | 50,27 |

| Surface area [m²] | 50,27 | 50,27 | 96,00 | 75,40 |

| Unrolled surface area [m²] | 50,27 | 64,00 | 50,27 | |

| Circumference [m] | 12,57 | |||

| Coefficient: Surface area/unrolled surface area []* | 4,00 | 1,50 | 1,50 | 1,00 |

| *Dimensionless except for the sphere, where the circumference/surface area coefficient [1/m] is given. | ||||

It is clear that the OLOID rolls with its entire surface, i.e. the coefficient 1. For the cube and the cylinder, it is clear that there are always surfaces that are not involved in rolling, hence the coefficients 1.5. The coefficient for the sphere must be treated with caution, as the circumference and a real surface were used for the calculation.

OLOID in water

This is what it looks like when everything presented is brought together in our OLOID systems: https://youtu.be/RekhS-bLbJo

- When the OLOID body is fully submerged below the water surface, the OLOID is an agitator with very high energy efficiency: it generates an impulse-like flow and achieves excellent homogenization of the mixture. Among other things, this promotes and accelerates the activation and maintenance of chemical-biological processes in (waste) water treatment (e.g. flocculation & precipitation).

- The inversion movement causes the water to develop its own form of flow, which promotes its self-cleaning ability.

- If the OLOID body is only partially immersed in the water, but at least half of it, it ensures an even oxygen input. However, this reduces the circulation effect. This characteristic is important for horticulture, lakes and fish farming, where the water needs to be stirred and aerated.

- In general, however, the OLOID is more of a circulation device than an aeration device.

- Please pay attention to the following while watching the video above:

- The emission of air bubble vortices represents the following:

- Impulse-like flow

- Oxygen enrichment

- Opening angle of the flow of 30°

- Self-cleaning effect of the OLOID body through water / air flow (cavitation)

- No risk of clogging on the agitator / OLOID body due to complete inversion

- The emission of air bubble vortices represents the following:

Mechanics of the OLOID gearbox

OLOIDs of different sizes are operated at different speeds. However, this is irrelevant for the principle of operation.

1 revolution of the motor delivers 4 pulses to the OLOID with 1 revolution of the head shafts; there is no gear ratio or reduction, but the pairing of the oval gearwheels causes the speed of the head shafts to change in steps = 2 pulses left and 2 pulses right. The positions of the oval gearwheels result in different speeds of the head shafts at the same time. If the speed of head shaft 1 is maximum, the speed of head shaft 2 is minimum and vice versa. It should be noted that the shaft speed can NEVER be 0 according to mechanical engineering terminology, as this is equivalent to a blockage. In other words: The shaft speed is almost 0!

Outlook / Perspective

By using an OLOID, the mash can be mixed in better during brewing and the mash is subjected to lower shear forces than with conventional mixing processes. This not only shortens the lautering time, but also reduces energy consumption by up to 80 %. As a result, we were able to brew the first OLOID beer in 2017 in collaboration with our cooperation partners.

- Optimization of applications by combining OLOID technology with any ventilation system (surface / pressure diffusers).

- An OLOID device is also suitable for viscous liquids and high solids contents.

- in the activated sludge process of wastewater treatment

- in an application in the treatment of cattle manure

- or in beer production

- Optimization of applications by combining OLOID technology with any ventilation system (surface / pressure diffusers).

- An OLOID device is also suitable for viscous liquids and high solids contents.

- in the activated sludge process of wastewater treatment

- in an application in the treatment of cattle manure

- or in beer production

Outlook / Perspective

By using an OLOID, the mash can be mixed in better during brewing and the mash is subjected to lower shear forces than with conventional mixing processes. This not only shortens the lautering time, but also reduces energy consumption by up to 80 %. As a result, we were able to brew the first OLOID beer in 2017 in collaboration with our cooperation partners.

Bibliography & further links

More information about the mathematics & physics of the OLOID and other geometric objects discovered and described by Paul Schatz: http://www.paul-schatz.ch/publikationen/

Further information about Paul Schatz, his life and work: http://www.paul-schatz.ch/home/

Various oloids and also invertible cubes are available from Kuboid GmbH: http://www.kuboid.ch/

- First 3D wind turbine http://vayu.swiss/

- Heliodome as an architectural concept for an energy-efficient house http://www.heliodome-de.com/

- FLOYD pendant light = lamp in the shape of an oloid

http://kuboid.ch/store/de/14-floyd-lampen - Ship propulsion by the Paul Schatz Foundation https://youtu.be/v381DYll1js

- Rhythmixx – a hand-operated inversion mixer according to Paul Schatz

http://www.kuboid.ch/store/de/15-rhythmixx

- First 3D wind turbine http://vayu.swiss/

- Heliodome as an architectural concept for an energy-efficient house http://www.heliodome-de.com/

- FLOYD pendant light = lamp in the shape of an oloid

http://kuboid.ch/store/de/14-floyd-lampen - Ship propulsion by the Paul Schatz Foundation https://youtu.be/v381DYll1js

- Rhythmixx – a hand-operated inversion mixer according to Paul Schatz

http://www.kuboid.ch/store/de/15-rhythmixx

Bibliography & further links

More information about the mathematics & physics of the OLOID and other geometric objects discovered and described by Paul Schatz: http://www.paul-schatz.ch/publikationen/

Further information about Paul Schatz, his life and work: http://www.paul-schatz.ch/home/

Various oloids and also invertible cubes are available from Kuboid GmbH: http://www.kuboid.ch/